Each piece of fancy colored diamond jewelry is extremely rare and will hold a unique and important value to its owner. A great deal of thought is applied in the design and an enormous amount of heart is invested in the whole manufacturing process. The aim is to create an alluring piece of jewelry that is designed exactly according to the customer's needs.

Crafting the jewelry is incredibly comprehensive and extremely detail oriented. While all diamond jewelry requires applied thinking and immaculate design, the design of fancy colored diamond jewelry is far more complex. In fact, center stone jewelry manufactured by LEIBISH, is custom made for each stone; unlike pave pieces, where the jewelry is first designed and only then are the stones applied.

From the moment the customer orders a specific jewelry piece, a meticulous process is followed until the finished product is ready. Manufacturing, designing, and crafting fancy colored diamond jewelry requires a delicate 9 - step procedure. Below are all the different stages of design through the process of manufacturing fancy colored diamond jewelry.

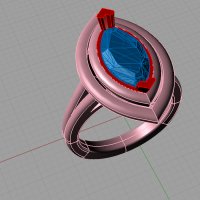

1: Designing the JewelryCreating a design that maximizes the color and beauty of the stone, according to the taste and personality of the client. |

2: Scanning the DiamondsScanning the diamond with a 3D lithography scanner, to create an accurate virtual model of the diamond. |

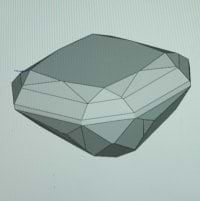

3: Creating the Virtual ModelA 3D virtual model is created, using a 3D CAD modeling application which the most advanced method for creation. |

4: Printing the ModelUsing a 3D printer, a physical model of the jewelry in its exact measurements is printed in a wax/resin material. |

5: Casting the ModelThe printed 3D model is casted with either Gold or Platinum and as a result of the material, it is then melted away. |

6: Assembling the JewelryAssembling the various pieces of the casted jewelry together in order to create a finished product. |

7: Setting the StonesSetting of all the diamonds inlcuded in the jewelry piece once the setting has been assembled. |

8: Polishing and EngravingThe finished jewelry piece is polished and engraved, which essentially helps bring out the luster and shine. |

9: Quality AssuranceAssessing the completed product to ensure every aspect of the jewelry was completed properly. |