< Previous Step | |

Step 2: Scanning the Diamonds |

| Next Step > |

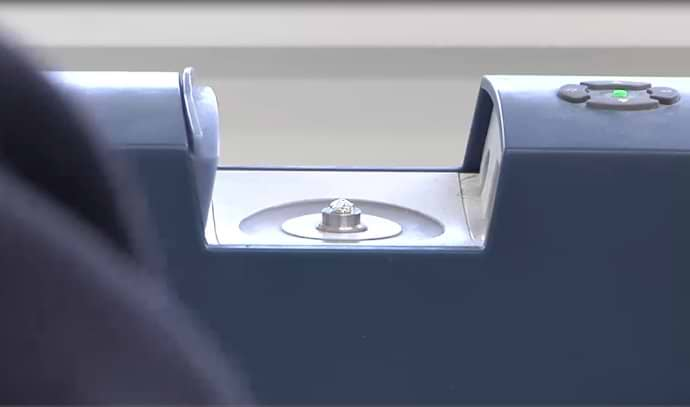

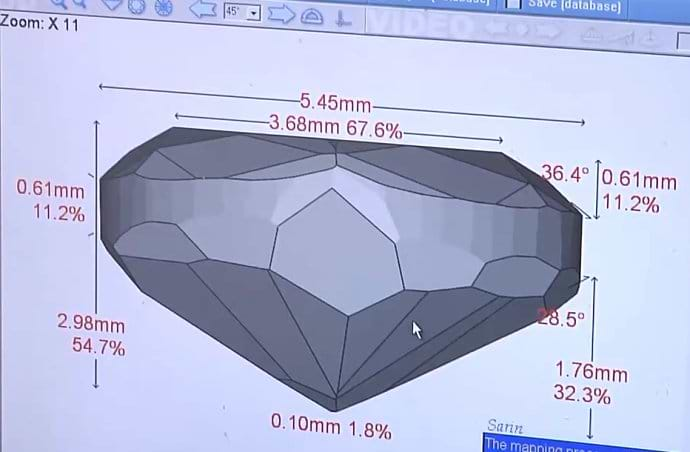

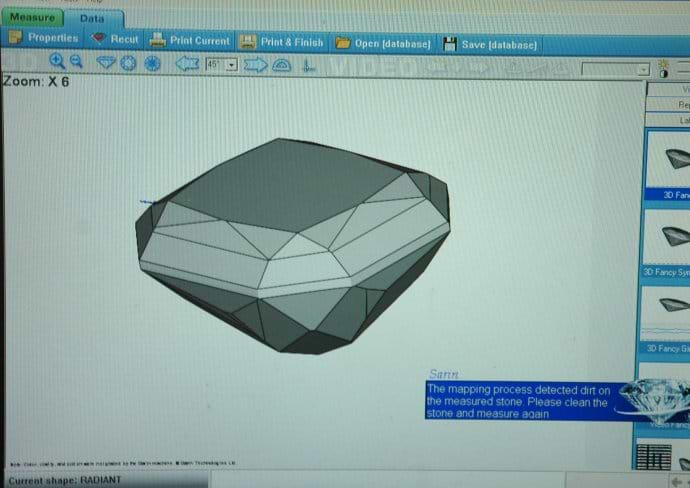

Each fancy colored diamond selected is inserted into a scanner to create a 3D virtual model of the stone, which accurately provides the dimensions, structure, and facet arrangement of the diamond.

With the online model of the stone, the designers can accurately create proportional sections of the jewelry so that it is as aesthetically pleasing as possible once assembled.

In order to maximize the potential of the colored diamond center stone, on many occasions a reflector is included into the structure of the jewelry. The reflector is placed underneath the stone, in the shape of a cup, by scanning the stone the contours of the pavilion of the stone are perfectly matched.

|

The 3D Scanner Enabling a Precisely Measured Virtual Model of the Diamond |

|

Richard Lewis, the Jewelry Production Manager, Viewing the 3D Virtual Model of the Diamond |

|

A Screenshot of the 3D Virtual Model with Some of the Exact Measurement of the Stone Displayed |

|

A Screenshot of the 3D Virtual Model without the Exact Measurement of the Stone Displayed |

Skip to any of the other steps in the manufacturing process of jewelry design

< Previous Step |

Step 2: Scanning the Diamonds |

Next Step > |